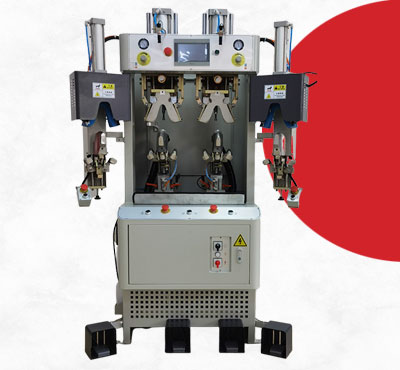

2 hot and 2 cold counter moulding machine for upper.

2 set of aluminium hot mould with silicon pad for reactivation counter stiffener.

2 set of aluminium cold mould with silicon pad for stabilising reactivator upper.

Economical version / Touch screen version available.

Pulling pincers in hot and cold stations for perfections.

Indirect cooling system for cold mould for safety and maintenance free.

Optical marking lamp enables proper positioning for moulding correct area.

Set of tooling included as per customer specified last sample.

2 hot and 2 cold toe moulding machine for upper.

1 set of aluminium hot pad for reactivation of toe upper.

1 set of aluminium cold mould with toe band for stabilising reactivator upper.

Economical version / Touch screen version available.

Indirect colling system for cold mould for safety and maintenance free.

Optical marking lamp enables proper positioning for moulding correct area.

1 set of tooling included as per customer specified last sample