Fully automatic PU pouring system, rotary 48/60 station direct injection on unit sole, direct injected shoes and suitable for making the complete safety shoes. Fully Automatic mould opening and closing, automatic Pu pouring device with complete inbuilt program for making shoes and soles by PU poring/injection process.

Max Displacement Volume - 150

Product Characteristics - Double-color, double density

Work Area - X, Y, Z = 380. 600. 10

Max Travel Speed - X, Y = 60m/min, Z = 24m/min

Rotating Speed of Pouring head mixture Shaft - 8600

Cleaning type of pouring head - Automatic

Rated Voltage - 380v

Unit Power - 20 - 40 Kw

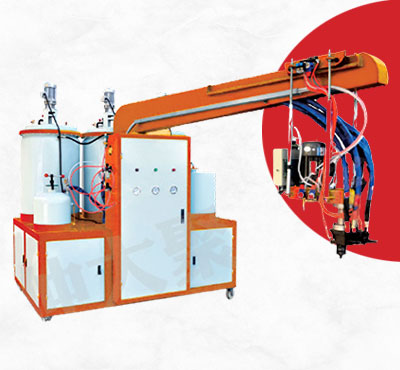

This is a manual PU pouring machine with single / double color and single/ double density with 2 or more tanks for different color of PU sole production. Machine consist of ISO tank and polyol tank with pigment tanks, automatic mould opening device with banana type equipped with 20 stations. This machine suitable for making high quality PU sole, sandals, foot beds, safety shoes, school shoes and other PU components.

Model No - SK-ZD - C2 - 250A

Tank Volume - 250

Mix of pouring head rotation speed - 2600 rpm

Measuring pump rotation speed control - Adopt frequency

Raw material temperature - Assemble computer control

Head control display by - Color’s 7 HMI Display

Total Power - 12 Kw

Heating mode - Electric heating (4.6 Kw)