Rubber sole with single or multi color, conductive rubber, rubber soles and other rubber finished product. Machine equipped with safety warning lights, safety curtains and two hand push button, protective shields. For more safety operation available station 6 - 10 with four column with middle plate open device.

Full automatic, one operator can handle multiple station to save labor cost and improve efficiency

Each station with independent operating control. Easy and light operation. Even female workers can operate the machine.

Whether use the middle plate device or not according to the production requirement.

Mould change will be simple and fast.

Pressure (Tons) - 150/200

Number of work station - 6 to 10

Size of the plate - 450 x 500 / 480 x 550 mm

Maximum stroke - 360

Power Specification - 380 v / 50 Hz

Operating mode - Fully Automatic

Heating Method - Oil / Steam / Electricity

Dimension - 8.1 x 2.4 x 1.76 m

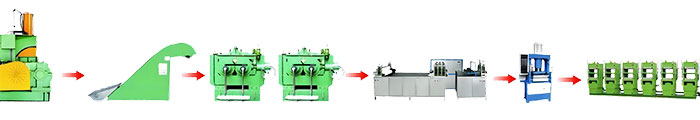

This is rubber compounding line set of machine consisting mixer, elevator, mixing mill, whirlwind barrel, vibrating conveyor and horizontal mixer. This is the process layout for rubber compounding to produce rubber compounding material to make rubber shoes. This specification and sizes may differ upon the volume and quantity of production.